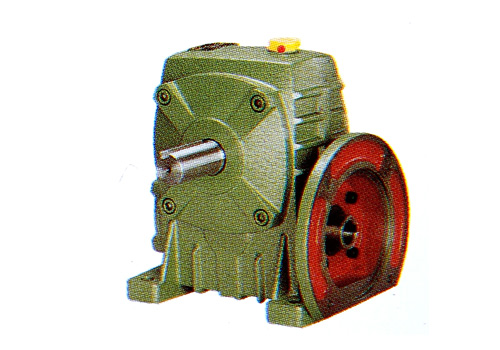

WPDA worm reducer

时间:2018-11-03 15:49 tags: Worm G R

The pinion is integrated with the shaft, called a gear shaft. This structure is used when the diameter of the gear is not related to the diameter of the shaft. If the diameter of the shaft is d and the diameter of the gear root circle is df, then when df- When d≤6~7mn, this structure should be adopted.When df-d>6~7mn, the structure in which the gear and the shaft are separated into two parts, such as a low-speed shaft and a large gear, is adopted.At this time, the gear and the shaft are connected with a fixed flat key in the circumferential direction, and the parts on the shaft are axially fixed by the shaft shoulder, the shaft sleeve and the bearing cover.Both shafts adopt deep groove ball bearings.This combination is used in the case of bearing radial load and small axial load.When the axial load is large, the combined structure of angular contact ball bearings, tapered roller bearings or deep groove ball bearings and thrust bearings should be adopted.The bearing is lubricated by the thin oil splashed when the gear rotates.The lubricating oil in the oil pool in the box seat is splashed by the rotating gear to the inner wall of the box cover, flows along the inner wall to the groove of the sub-box surface, and flows into the bearing through the oil guide groove.When the circumferential speed of the oil-soaked gear υ≤2m/s, grease should be used to lubricate the bearing. In order to avoid the possibility of splashing thin oil from washing away the grease, an oil retaining ring can be used to separate it.In order to prevent the loss of lubricating oil and external dust from entering the box, a sealing element is installed between the bearing end cover and the extension shaft.

型号大全:WPDA50、WPDA60、WPDA70、WPDA80、WPDA100、WPDA120、WPDA135、WPDA155、WPDA175、WPDA200、WPDA250。

- Previous:WPDO worm reducer

- Next:WPA reducer