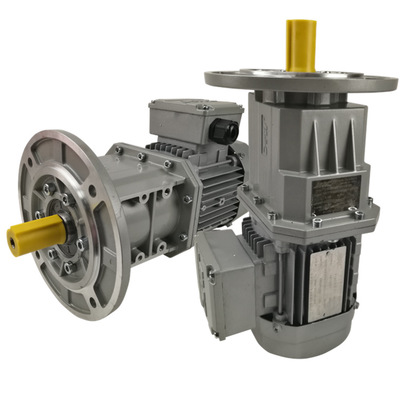

Aluminum housing helical gear reducer

时间:2018-11-20 10:46 tags: Gear reducer

Aluminum shell helical gear reducers are generally used for low-speed and high-torque transmission equipment. The ordinary reducer of the motor will also have several pairs of gears with the same principle to achieve the ideal reduction effect. The ratio of the number of teeth of the large and small gears is the transmission ratio.With the continuous development of the reducer industry, more and more companies have used the reducer.

Aluminum housing helical gear reducer 1, R series coaxial helical aluminum housing helical gear reducer is manufactured in accordance with international technical requirements and has high technological content

2. Space saving, reliable and durable, high overload capacity, power up to 132KW;

3. Low energy consumption, superior performance, and the reducer efficiency is as high as 95% or more;

4. Low vibration, low noise and high energy saving;

5. Choose high-quality forged steel materials, rigid cast iron box, and the gear surface has undergone high-frequency heat treatment;

6. After precision machining to ensure shaft parallelism and positioning bearing requirements, the reducer forming the helical gear transmission assembly is equipped with various types of motors, combined into mechatronics, which can guarantee the quality characteristics of the product.

Scope of application:

Reducer:

1. The high-speed shaft rotation is not more than 1500 rpm.

2. The circumferential speed of the gear drive is not more than 20 m/s.

3、工作环境温度为-40-45℃,如果低于0℃,启动前润滑油应预热至0℃以上。

4. Aluminum housing helical gear reducer can be used for forward and reverse rotation.

Machine features:

1. The gear is made of high-strength low-carbon alloy steel by carburizing and quenching. The hardness of the tooth surface is HRC58-62. The gears are all CNC gear grinding technology with high precision and good contact.

2. High transmission rate: single-stage greater than 96.5%, double-stage greater than 93%, and three-stage greater than 90%.

3. Smooth operation and low noise.

4. Small size, light weight, long service life and high carrying capacity.

5. Easy to disassemble and inspect, easy to install

- Previous:Parallel shaft helical gear reducer

- Next:Nothing